Shilajit Supplement: Safety, Testing, Compliance Guide

Feb 09, 2026

Shilajit has transitioned from traditional use to a mainstream dietary supplement ingredient, introducing mineral and fulvic acid content to modern formulations. Increased utilization requires manufacturers to address safety, testing, and regulatory compliance due to the substance’s geological accumulation of heavy metals and batch variability. Effective oversight requires knowledge of purification outcomes, analytical testing capabilities, and the regulatory frameworks applicable to these products.

What Is a Shilajit Supplement?

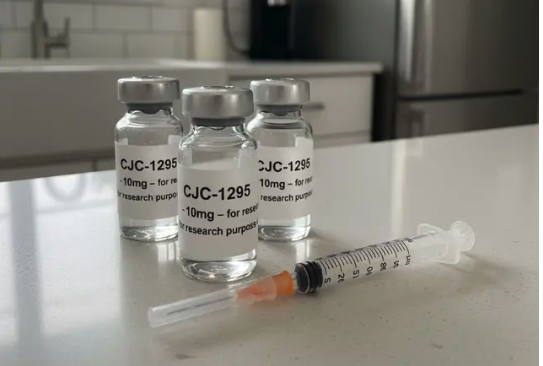

Shilajit is a naturally occurring mineral-rich phytocomplex formed through the decomposition of plant material in mountainous environments. Visually it is a black paste that is found entwined with rock requiring grinding and purification to process into a usable ingredient. Supplement products typically standardize for fulvic acid concentration and implement purification steps to reduce natural contaminants. Shilajit is commercially available as a solid, paste, or extract, and contains minerals such as iron, calcium, magnesium, manganese, and selenium. Potential quality control concerns include inclusion of naturally present substances that may be banned, heavy metals concerns, and synthetic shilajit that is not a legal dietary supplement ingredient and may vary in the true contents in the material. The BSCG Certified Quality third-party certification is available to brands and consumers that want to verify that a shilajit supplement is authentic and natural, and screen for heavy metals and banned substances to ensure product quality.

Heavy Metals and Quality Concerns in Shilajit Supplements

Raw shilajit contains heavy metals, including lead, mercury, arsenic, cadmium, aluminum, chromium, and thallium, resulting from prolonged geological formation processes. Peer-reviewed research published in 2025 documented thallium levels of up to 0.095 µg per tablet in some commercial shilajit supplements, exceeding those found in select raw materials.

Geographical differences in shilajit composition result from variations in altitude, climate, and surrounding rock formations. This inconsistency complicates the establishment of universal safety thresholds and poses challenges in maintaining quality within and between batches from the same region.

Fulvic acid concentrations vary substantially across commercially available shilajit, primarily due to source variability and differences in extraction and standardization techniques. ConsumerLab documented fulvic acid levels ranging from 6.9 mg to 2,206 mg per serving, representing a nearly 32,000% variation linked to differing production controls.

Purification distinguishes raw shilajit, which contains the full range of natural contaminants, from processed material. The efficacy of purification processes in removing risks depends on procedural rigor and the scope of post-processing analysis.

Potential Presence of Ephedrine Alkaloids in Shilajit

One unique concern with Shilajit is the potential presence of banned substances that may come from the degraded plant material, for instance ephedrine alkaloids. As a product that is made up of degraded plant material the actual constituents may vary significantly depending on the region that the shilajit is harvested. Much of the authentic shilajit comes from the high mountains of Pakistan. One study looked at the prevalence of plants in one specific region in Pakistan and found that that Ephedraceae species, specifically Ephedra gerardiana, made up 1.190% of the plant species in the study area. This could put shilajit products at risk of containing substances like cathine, ephedrine or pseudoephedrine.

Testing and Purification Standards

Water extraction, filtration, temperature control, centrifugation, and optionally UV treatment are common purification steps for shilajit. Preservation of bioactive compounds such as fulvic acid during these processes is essential. Accurate claims about the finished product require analytical verification. Low-temperature vacuum technology can support fulvic acid retention, but verification remains critical.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) enables detection of heavy metals at the parts-per-billion scale and represents the industry standard for contaminant screening. BSCG's Certified Quality program uses this analysis to test for heavy metals, pesticides, and microbiological agents. Minimum testing requirements include lead, mercury, arsenic, and cadmium. Heavy metals limits from US Pharmacopeia are considered.

Testing protocols for microbiological and mycotoxin content must address total aerobic bacteria, yeast and mold, and specific pathogens such as Escherichia coli and Salmonella. Relevant industry standard methods and techniques include AOAC methods, US Pharmacopeia methods and the FDA Bacterial Analytical Manual (BAM).

Certificates of Analysis (COAs) should clearly state testing methodologies (including ICP-MS, AOAC, or IRXNK, as appropriate), fulvic acid percentage, detailed heavy metal results with detection limits, date of testing, and batch identification. Quality assurance requires analytical confirmation at each stage, beginning with raw material and concluding with the finished product. Product specifications outline intended ingredient composition, while analytical testing provides empirical confirmation.

Fulvic acid determination is sensitive to methodology. ISO 19822:2018 provides the most accurate industry protocol, albeit with increased time and cost. Methods utilizing Total Organic Carbon (TOC) or titration can produce inflated measurements. Many large contract laboratories employ faster, less-specific protocols that may deliver inaccurate values.

While targeting fulvic acid by HPLC is a standard way to evaluate quality of shilajit supplements it is not necessarily ideal as it synthetic variants that are not legal dietary supplements may still pass a fulvic acid test. A better way to verify the authenticity of shilajit supplements is using FTIR analysis that looks at an overall profile for shilajit not just a single component or compound.

Third-Party Certification is Available to Verify Quality

Good Manufacturing Practice (GMP) certification confirms facility adherence to defined production processes but does not verify specific active compound or contaminant content in a given batch. Third-party certification for finished products is available to help brands and consumers verify shilajit quality.

Certifications from organizations such as NSF International or USP Verified are uncommon for shilajit products due to testing complexity and inherent volatility of shilajit’s composition. The existence or absence of such certifications does not alone determine product acceptability. BSCG has worked with partners to create an FTIR approach to verifying shilajit quality that is now incorporated in the BSCG Certified Quality program. Critical evaluation requires confirming equivalent testing approaches and transparent documentation.

Independent laboratory analysis can verify the absence of significant heavy metal and microbiological contamination but cannot address all potential risks. Testing only provides a result for the analyzed batch, necessitating routine verification across production lots to demonstrate quality consistency.

Comprehensive risk mitigation includes supplier audits, raw material screening prior to processing, in-process controls, final product testing, and sample retention for future assessment. BSCG's protocol includes identity verification, label claims substantiation, screening for environmental contaminants, and testing for over 450 banned substances. This comprehensive structure addresses natural contaminant and adulteration risks specific to shilajit supplementation. For those brands looking to ensure protection of athletes, military service members or other professionals subject to strict drug testing the BSCG Certified Drug Free program tests every lot for banned substances drastically reducing the chance of contamination that could lead to an inadvertent positive drug test.

Claims and Labeling Risk

In the United States, shilajit is regulated as a dietary supplement under the Dietary Supplement Health and Education Act (DSHEA) of 1994. Manufacturers are permitted to make structure/function claims such as "supports energy metabolism" but cannot state disease treatment, cure, or prevention attributes. The Food and Drug Administration (FDA) does not pre-approve dietary supplements; regulatory oversight focuses on safety and label accuracy after market introduction.

Claims that imply testosterone enhancement or anti-aging properties require careful evaluation to avoid regulatory concerns. Many testosterone-focused products exclude direct claims regarding testosterone increase to remain within permissible structure and function parameters. All claims must be substantiated with valid evidence in accordance with regulatory guidelines.

Fulvic acid content statements must be based on validated analytical testing. Given documented variability among commercial shilajit preparations, unsupported fulvic acid percentage claims present regulatory and reputational risks to the brand.

While natural authentic shilajit qualifies as a legal dietary ingredient as it was used in cultural medicine as a food prior to 1994 when DSHEA took effect, synthetic shilajit would likely not be considered legal. The popularity of shilajit has grown so fast that many people in the industry believe that much of the shilajit on the market is fake. Again, testing should be done to verify the authenticity but to date the industry has relied on HPLC testing for fulvic acid that does not adequately verify the integrity of the shilajit.

Considerations for Brands That Sell Shilajit Supplements

Shilajit suits advanced dietary formulations where brands can implement transparent raw material sourcing, robust testing, and detailed communication regarding purification. Mineral and fulvic acid content can contribute distinct formulation value if controlled through comprehensive oversight and documentation. Detailed supplier engagement, consistent batch testing, and third-party verification allow manufacturers to demonstrate product differentiation in a category characterized by wide quality variation.

The technical complexity associated with shilajit may exceed operational capacities for brands lacking systems for routine testing and supply chain management. Shilajit demands greater due diligence compared to many botanicals. Without reliable verification of every batch, ongoing certificate of analysis management, and the ability to address contamination, brands may find alignment with shilajit inconsistent with internal operational standards.

Documentation of sourcing, purification, and test results is critical for consumer and retailer confidence. Brands unable to provide this information should anticipate increased scrutiny. Marketing claims must be substantiated with data rather than relying on ambiguous references to purity or origin.

Some companies adopt alternative ingredients with more predictable properties, reduced risk of contamination, or higher levels of clinical evidence, seeking comparable formulation outcomes with less complexity. The recommendation to include shilajit in product formulations should rest on quality control capacity and documented evidence rather than trend alignment. Third-party certification programs are available to brands that wish to verify the quality of products and represent that quality to consumers.

Broader Implications for Shilajit in Dietary Supplements

Global regulatory authorities continue to intensify scrutiny of heavy metal contamination in supplements. Canadian agencies have issued warnings and may detain unauthorized Ayurvedic imports due to contaminant detection. The European Union applies extensive requirements for shilajit as a novel food or herbal supplement, mandating comprehensive safety assessments. Australia’s Therapeutic Goods Administration upholds strict herbal supplement standards and limits entry of unverified products at the border.

Industry trends now view third-party verification as a baseline expectation rather than a differentiation factor. Incidents involving counterfeit or adulterated shilajit have impacted consumer trust and advanced regulatory consideration. In response, reputable companies are increasing investment in supply chain transparency, laboratory validation of composition, and analytical verification of fulvic acid and contaminant content.

Continued research into fulvic acid standardization is likely to evolve industry quality expectations. As analytical protocols advance and regulations adapt, disparities between manufacturers with comprehensive controls and those with minimal oversight will become more transparent. Testing services encompassing heavy metals, pesticides, solvents, microbiological agents, ingredient identity, and nutritional markers address the key areas of quality concern in shilajit production. This integrated approach provides a framework for responsible manufacturing.

FAQ

Is shilajit regulated as a dietary supplement in the U.S.?

Shilajit is subject to regulation as a dietary supplement under DSHEA. The FDA monitors post-market safety and labeling compliance. Manufacturers bear full responsibility for ensuring product safety prior to consumer distribution.

Why does shilajit often contain heavy metals?

The geological formation of shilajit as a product of decomposed plant matter and mineral interaction results in the inherent accumulation of heavy metals such as lead, mercury, arsenic, and cadmium. These contaminants are present in the raw material and must be addressed through purification and verification testing.

How is shilajit purified for supplements?

Water extraction, filtration, temperature regulation, centrifugation, and ultraviolet treatment are established purification processes for shilajit. Ensuring the efficacy of these steps requires analytical testing of the finished product to confirm both bioactive content and successfully reduced contaminants.

What testing should shilajit supplements undergo?

Testing protocols for shilajit supplements should include ICP-MS for heavy metals (lead, mercury, arsenic, cadmium), comprehensive microbiological assessment, mycotoxin screening, and validated fulvic acid quantification. Annual analyses should verify label claims, environmental contaminant levels, and screen for relevant banned substances.

Is fulvic acid the same as shilajit?

Fulvic acid is one component of shilajit. Shilajit comprises more than eighty additional minerals and organic compounds. Commercially standardized shilajit preparations commonly target 15-20% fulvic acid content, but laboratory analyses demonstrate substantial variability among products. Fulvic acid can also come from sources other than shilajit and can be synthesized.

How should brands communicate shilajit safety responsibly?

Brands must provide accurate, transparent testing results, supplier data, and detailed purification procedures. Permitted claims are those clearly grounded in structure/function definitions, substantiated by reliable data, and unambiguously separated from disease treatment assertions. Third-party certification and public COAs support transparency and commitment to recognized manufacturing standards and showcase product quality to consumers.

.png)