Clean Label Project Certification for Supplements: What Brands Need to Know

Feb 04, 2026

Supplement brands are required to demonstrate transparency in manufacturing and sourcing practices to address rising expectations from consumers and retailers. Documentation of compliance with safety standards beyond minimum regulatory requirements has become a business necessity. Third-party testing organizations, such as the Clean Label Project, operate to independently assess products for the presence of contaminants not typically declared by manufacturers.

The marketplace features a range of certification programs, each defined by their respective testing scopes and recognition. Certain programs focus on the identification of banned substances relevant to athletes, while others confirm label claims or conduct manufacturing facility audits. Clean Label Project specifically addresses environmental and industrial contaminants that are typically not included in supplement quality control testing.

The regulatory oversight for dietary supplements in the United States remains limited. The U.S. Food and Drug Administration (FDA) implements post-market enforcement rather than pre-market approval, placing the responsibility for safety and quality on manufacturers. Voluntary third-party certifications enable brands to document product testing and signal their compliance efforts to stakeholders.

What Is Clean Label Project?

Clean Label Project independently tests consumer products for environmental and industrial contaminants. The organization acquires products in retail settings and subjects them to analysis in ISO-accredited laboratories for specific contaminants as determined by the program focus using standards derived from California’s Proposition 65, European Union regulations, U.S. state and federal regulations, and proprietary category data. Achieving certification confirms compliance with these standards at the time of sampling. The certification is not regulatory approval and does not guarantee continuing compliance for future production lots.

Clean Label Project Compared to Regulatory and Industry Standards

FDA regulations mandate Good Manufacturing Practices (GMP) for supplement production but do not require pre-market approval of products. Manufacturers bear the legal responsibility to ensure product safety and accurate labeling including screening for environmental contaminants. The FDA primarily acts through post-market surveillance and enforcement actions in instances of adulterated or misbranded products.

Clean Label Project certification operates as a voluntary program. Its contaminant testing aligns with California Proposition 65 thresholds or European Unions requirements which may be more stringent that typical industry standard testing. These thresholds diverge from federal safety limits and are not universally recognized by all regulatory bodies as the primary benchmarks for safety.

Other third-party programs differ in their approach by adding in depth audits for GMP compliance or label claim and ingredient verification testing or screening for banned substances. NSF International evaluates products against NSF/ANSI 173 standards for the Content Certified program and inspects facilities for GMP compliance in the GMP Certified program, while the NSF Certified for Sport program screens for banned substances. USP Verified confirms ingredient identity, strength, and purity through direct product testing and facility reviews in addition to conducting GMP compliance reviews.

Another leading international third-party certification provider BSCG also incorporates GMP compliance reviews with banned substance screening and quality control process and testing evaluation. The BSCG Certified Drug Free program tests every lot for more than 450 banned substances, while the BSCG Certified Quality program tests annually for label claims, environmental contaminants, and banned substances. A BSCG Certified CBD program is available to hemp and CBD product brands to verify cannabinoid and CBD claims, apply a strict THC limit for drug testing protection, testing for heavy metals, pesticides, and microbiological agents and banned substances.

The testing methodologies and program scopes vary considerably among certifying bodies. Some restrict testing to contaminants, while others conduct label claim verification, manufacturing audits, or ongoing monitoring. Independent supplement testing programs often require batch-specific testing, biennial facility audits, and the maintenance of public certification databases to validate the status of particular production lots.

GMP compliance establishes the systematic foundation for quality management in supplement manufacturing. Clean Label Project evaluates GMP or food safety certificates for product manufacturers as part of the process. BSCG and NSF go a little more in depth by reviewing the quality control process, supplier qualification, adverse event reporting, recall procedures and more. GMP requirements encompass procurement, production, equipment upkeep, sanitation, documentation, and complaint resolution. Testing of finished products serves to verify these processes but cannot compensate for deficiencies in underlying manufacturing protocols.

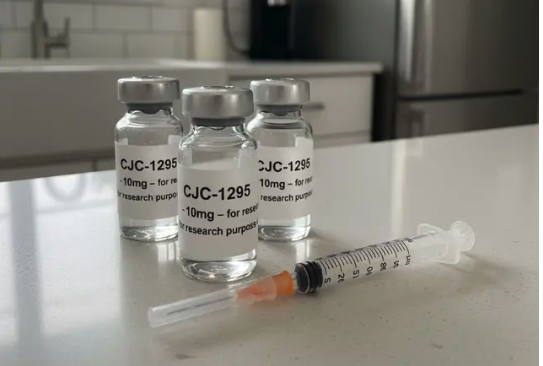

Key Contaminants Measured in Clean Label Testing

Clean Label Project applies comprehensive contaminant screening focused on the specific contaminants relevant to each certification. Heavy metals such as arsenic, cadmium, lead, and mercury are part of its scope. Plasticizers, including BPA, BPS, and various phthalates, are screened alongside more than 300 common pesticides, such as glyphosate.

Tested contaminant thresholds match California Proposition 65 standards. Lead has a threshold of 0.5 µg per day, cadmium is established at 4.1 µg per day for oral exposure, and the permissible daily exposure for mercury is 0.3 µg. For oral arsenic exposure, the threshold is 10 µg per day. Glyphosate is limited to 1,100 µg per day in this framework.

These Proposition 65 thresholds function as triggers for warning requirements, not absolute safety limits. Federal authorities and international organizations utilize different standards for regulated contaminants. For example, industry standards such as USP <2232> and ANSI 173 define permitted daily exposures for heavy metals which may not align with those set forth under Proposition 65.

Analytical detection methods influence the testing process. The identification of a contaminant does not automatically equate to a safety violation; appropriate assessment depends on established exposure limits and the totality of expected dietary intake.

Variability between production batches remains a persistent risk factor. Changes in raw material sources, manufacturing processes, and environmental conditions affect contaminant profiles. Certification of a single batch provides information relevant to that instance only. Ongoing process controls and periodic testing support product consistency across production runs. Annual testing is a check on product quality but does not ensure quality for each lot produced.

Comprehensive contaminant analysis often necessitates services beyond those offered by Clean Label Project. Expanded testing services may address microbiological hazards, including total plate count, yeast, mold, coliforms, E. coli, Staphylococcus aureus, and Salmonella, along with testing for production solvents and aflatoxins. Ongoing testing for environmental contaminants is required by GMP but manufacturers determine the specifics and testing frequency. Program and testing requirements can differ by providers.

Certification and Compliance: Distinctions and Limitations

Third-party certification documents that a specific product lot met set testing criteria at the time of assessment. Certification is not a substitute for ongoing quality assurance systems and does not provide prospective guarantees. Changes in manufacturing, supply chains, or processes may alter product composition in future batches.

Foundational GMP systems support ongoing compliance. These systems involve supplier qualification, ingredient analysis, process validation, equipment maintenance, environmental controls, and thorough documentation. Certification serves to confirm, but not replace, these essential processes.

Certifications typically go above and beyond industry standards when evaluating product quality. In the case of Clean Label Project, testing employs lower limits for heavy metals than typically used in the industry and it covers things like glyphosates that may not be included in industry standard pesticide testing.

The validity of any certification is limited to the tested samples or lots. The presence of a seal on product packaging indicates that a product is participating in a certain program, but does not ensure that actual lot in hand has been tested. Verification of lot-specific certification status via public databases remains necessary. Clean Label Project tests products annual, as does the NSF Contents Certified and BSCG Certified Quality program. Banned substance testing programs usually do more frequent testing with the BSCG Certified Drug Free program testing every lot and the NSF Certified for Sport program testing representative lots at unspecified frequency.

No certification program can eliminate all risks associated with contaminants or banned substances. Published analyses show that absolute assurance is not possible. Analytical limitations and the scope of targeted compounds influence what is detectable and reportable within each program.

Testing cycles introduce additional exposure concerns. Products certified annually undergo only periodic assessment. Changes to suppliers, formulations, or manufacturing methods between test cycles may escape detection until the next scheduled review. Greater protection is afforded through frequent or event-triggered testing protocols.

Certification and compliance systems operate most effectively when integrated. Certification programs combining identity verification, label claim testing, contaminant analysis, and GMP audits provide broader risk management than programs that focus exclusively on a single dimension.

Application of Clean Label Project Certification for Brands

Clean Label Project certification can document a brand’s compliance with specified contaminant thresholds at the time of testing. The seal communicates that a product underwent independent laboratory analysis and met program standards. Markets that emphasize transparency or environmental safety may attribute credibility to this certification.

Certain retailers and e-commerce platforms recognize Clean Label Project certification. For example, Amazon's Compliance Fast Track includes Clean Label Project as a valid third-party certification provider for dietary supplements, along with BSCG and NSF, which may facilitate regulatory documentation for sellers on its platform.

Utilizing Clean Label Project certification as the sole indicator of product quality remains insufficient. Brands lacking thorough GMP controls, comprehensive testing protocols, or supplier oversight continue to face tangible risks. Certification evidences one aspect of product quality, not comprehensive assurance of safety, manufacturing consistency, or compliance with banned substance lists.

Brands are required to present certification claims accurately. For example, stating a product is "Clean Label Project Certified" when certification is current and applicable is factual. Phrasing that implies a product is "pure," "safe," or "free from contaminants" based solely on testing results misrepresents the scope and meaning of certification. Certification confirms conformance with defined criteria for tested samples only.

Brands targeting specific concerns, such as banned substances in sport, require additional testing beyond Clean Label Project certification. Clean Label Project does not assess the presence of anabolic steroids, stimulants, or substances proscribed by sports authorities. Comprehensive programs incorporate those elements as part of a broader compliance strategy.

Certification processes may identify quality management gaps by detecting elevated contaminant levels. Properly implemented, certification serves as a compliance tool that directs attention to raw materials, process controls, or supply chain issues. Certification also represents product quality to consumers and builds trust in product integrity.

Implications for Supplement Brands

Third-party product testing has become an established component of quality assurance infrastructure for dietary supplements. Retailers, professional associations, and informed consumers often request documentation demonstrating compliance with standards higher than the legal minimum. Brands that integrate testing and certification into their quality management systems align more effectively with contemporary stakeholder expectations.

Certification programs differ in testing scope, threshold standards, and third-party recognition. Clean Label Project focuses on screening for certain environmental and industrial contaminants. Alternative certifications address banned substances, label accuracy, GMP compliance, or multiple dimensions. Brands should select programs based on alignment with customer requirements, product categories, and organizational risk management policies.

Consistent and frequent testing provides stronger safeguards than strictly periodic or one-time certification. Market analyses have found that between 10% and 30% of dietary supplement products in some categories contain prohibited substances. Regular testing, in conjunction with GMP audits and supplier due diligence, supports reduced risk of contaminated or adulterated goods reaching the market.

Transparency regarding testing methodology, scope, and results supports brand credibility. Brands are expected to report what was tested, which standards apply, and any inherent limitations of the certification. Claims that go beyond substantiated evidence, or that imply guarantees not offered by the certification process, may expose organizations to regulatory or legal scrutiny.

Integrating multiple layers of quality assurance, such as identity verification, label accuracy, contaminant screening, banned substance analysis, and independent audits, enhances risk management capabilities. Comprehensive certification programs support this integrated approach more thoroughly than single-focus solutions.

Frequently Asked Questions

Is Clean Label Project certification required for supplements?

Clean Label Project certification is not a legal or regulatory requirement. FDA regulations do not require pre-market approval for dietary supplements, and participation in Clean Label Project is voluntary. Manufacturers determine whether to submit products for independent review subject to their quality and marketing objectives.

Does Clean Label Project certification signify that a product is contaminant-free?

Certification confirms that tested samples complied with specified contaminant thresholds at the time of testing. It does not guarantee the absolute absence of contaminants or eliminate all potential risks for all users. The annual testing frequency is suggestive of product quality across other lots but does not guarantee quality in untested lots.

What are the recommended practices for brands using Clean Label Project certification?

Brands should present certification status transparently, specify to which lots and standards certification applies, and avoid making claims of absolute safety, regulatory endorsement, or assurances unsupported by the scope of the testing.

Does Clean Label Project testing identify compliance gaps?

The testing may identify batches that exceed contaminant thresholds, which allows brands to examine supply chains, materials, and manufacturing processes for sources of the issue. Certification testing can be a valuable tool for proactive compliance management and for building consumer trust.

How does Clean Label Project compare to other supplement certification programs?

Clean Label Project assesses environmental and industrial contaminants based on California Proposition 65 standards, European Union standards, or other customized limits. Other programs, including those by NSF, USP, and BSCG, may broaden their scope to include banned substance detection, label verification, and GMP auditing. Recognition and testing approaches vary among these programs and must be reviewed carefully by consumers to ensure they get the protection they are seeking.

Does Clean Label Project certification replace GMP compliance?

Certification does not replace GMP requirements. GMP establishes systematic controls for production consistency, supplier management, and thorough documentation. Certification verifies outcomes but does not substitute for comprehensive process management. Clean Label Project verifies GMP or food safety audits for product manufacturers as part of the process.

.png)